Introduction

Industrial plants face the constant challenge of maintaining productivity without increasing energy costs. Thanks to IoT, it is now possible to monitor consumption, power, power factor, and machine status in real time, enabling data-driven decisions.

1. Energy control and efficiency

IoT sensors installed on electrical panels record voltages, currents, and power on each line. This makes it possible to identify overloads, imbalances, and energy losses, avoiding unplanned stops and improving overall energy performance.

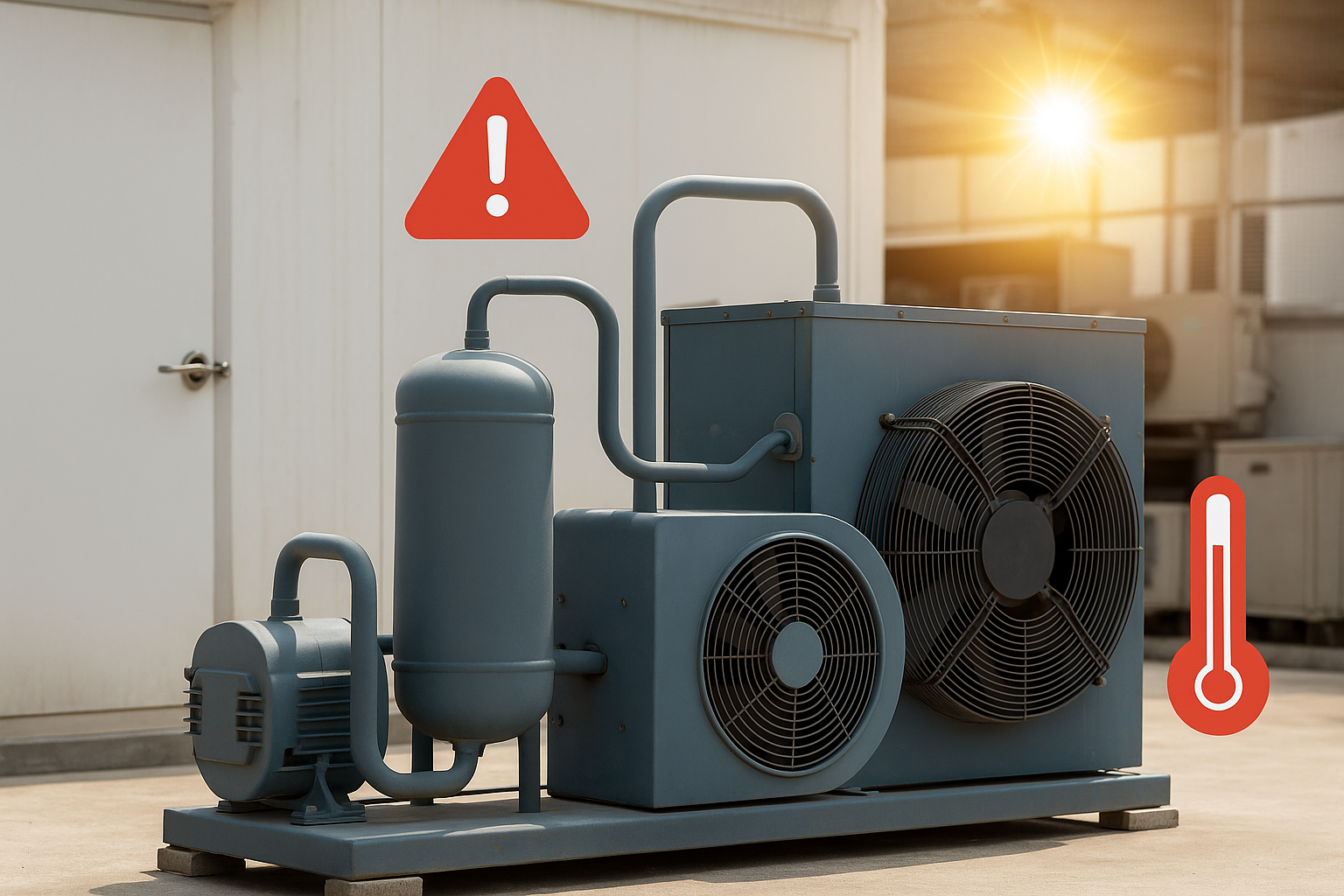

2. Critical process variables

Temperature, pressure, flow, or vibration: any deviation outside the range can affect quality or generate defects. Continuous monitoring keeps process conditions under control and generates automatic alerts for any anomaly.

3. Reports and traceability

The collected data is transformed into automatic reports and auditable records, making compliance and internal audits easier.

QBIT Solution

QBIT lets you visualize consumption, production, and alerts on a single platform. With customizable dashboards and smart alarms, industrial plants can operate with maximum efficiency. Learn more about QBIT Industrial.