Introduction

The Internet of Things (IoT) is transforming asset management with predictive maintenance: a strategy that uses sensors and data analysis to anticipate failures, plan interventions, and optimize resources.

Unlike corrective maintenance or calendar-based preventive maintenance, the predictive approach monitors in real time and detects anomalies before they become costly downtime.

What is predictive maintenance?

It consists of continuously measuring critical variables of the process and the equipment to estimate the optimal time for intervention. This avoids replacing parts too early or reacting too late to failures.

IoT sensors and signals to monitor

IoT sensors make it possible to track variables such as:

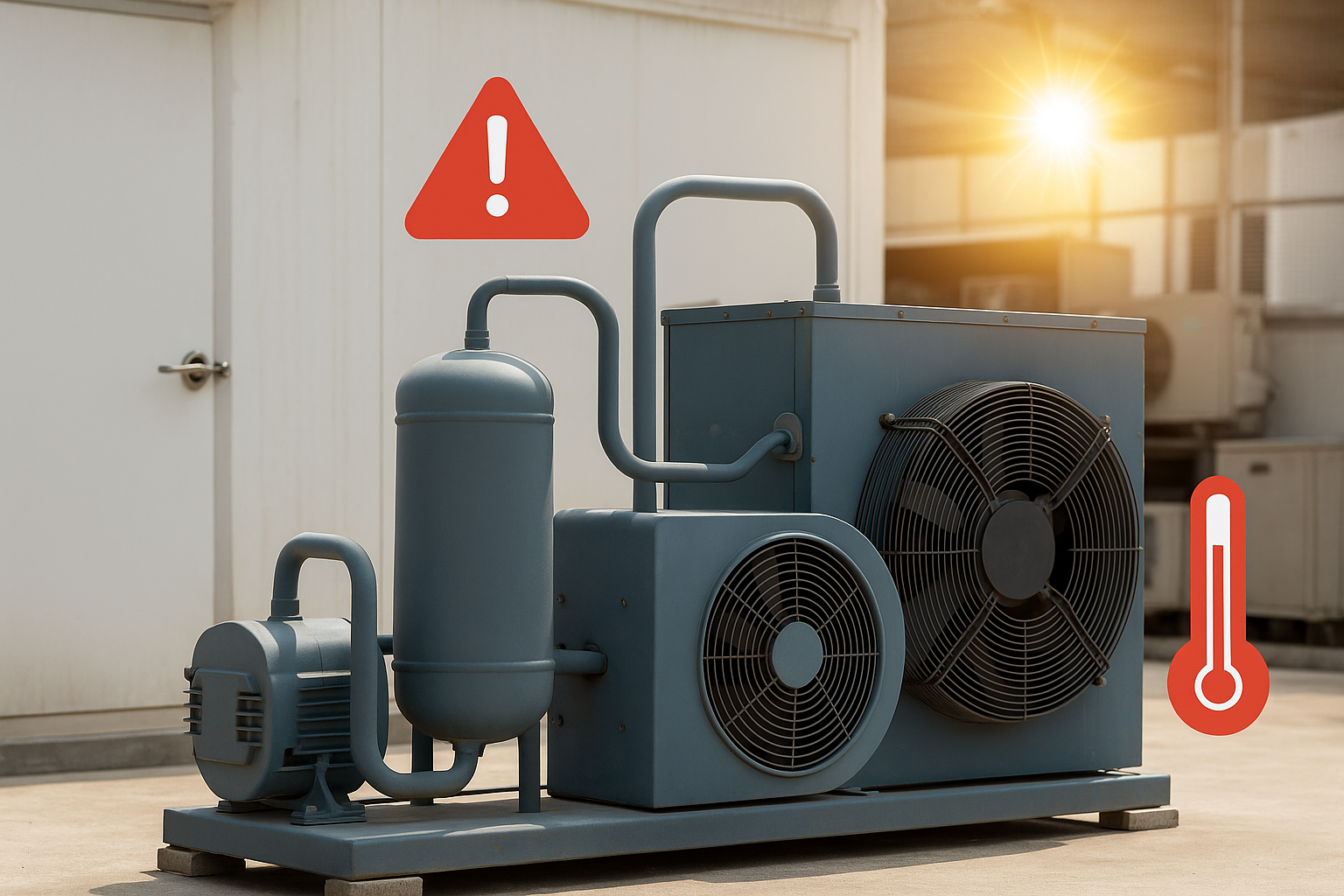

- Temperature and humidity: cold rooms, motors, electrical panels.

- Vibration and ON/OFF status: early detection of imbalance or unexpected stops.

- Electric consumption: energy patterns that anticipate wear or inefficiencies.

- Modbus integration: data from existing PLCs and industrial equipment.

Key benefits

- Less unplanned downtime: early alerts and timely decisions.

- Cost reduction: interventions when needed, without excessive maintenance.

- Greater safety: critical failures and risky conditions are prevented.

- Energy efficiency: consumption is optimized and the footprint is reduced.

QBIT IoT for predictive maintenance

Agile implementation, wireless sensors, industrial gateways, and dashboards with real-time alerts. You start with one machine or line and scale to the rest without friction.

Ready to make the leap? Contact us and let us design your predictive maintenance plan with IoT.